Fostering eco-industrial parks in Viet Nam

24 January 2020 UNIDO

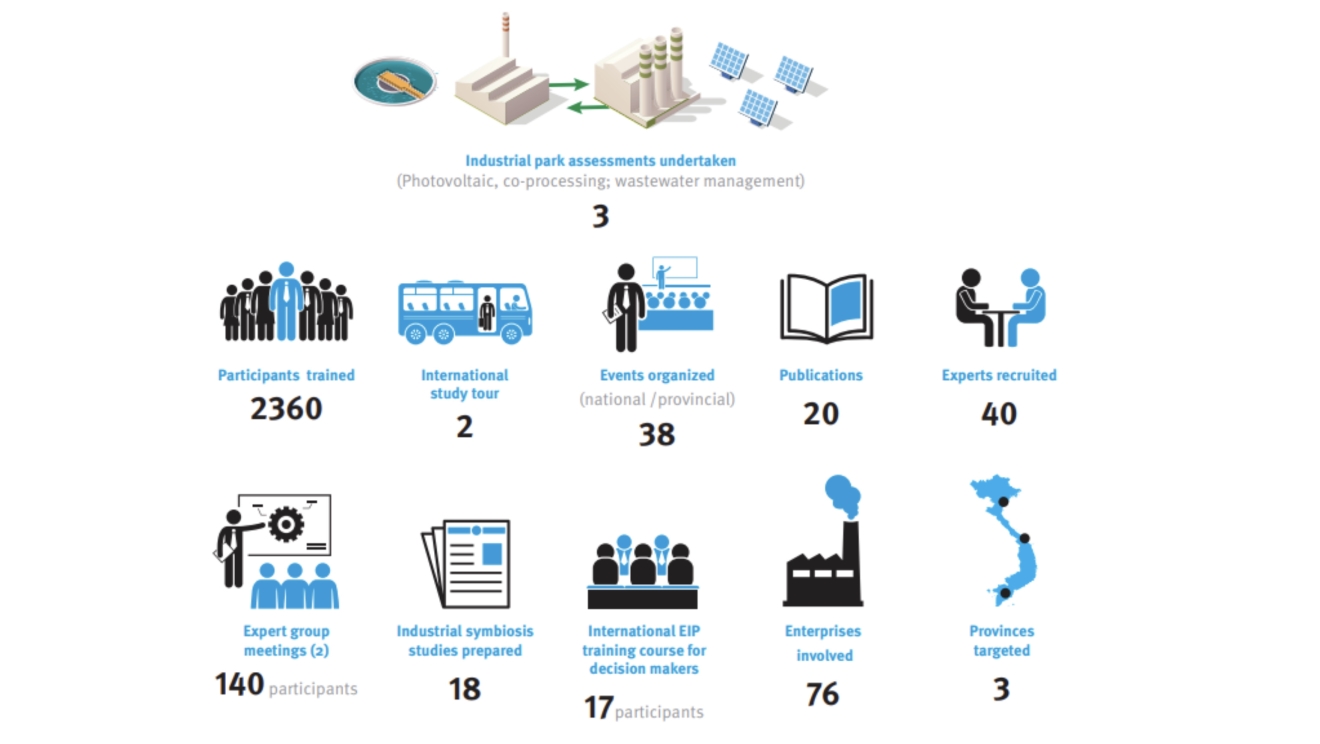

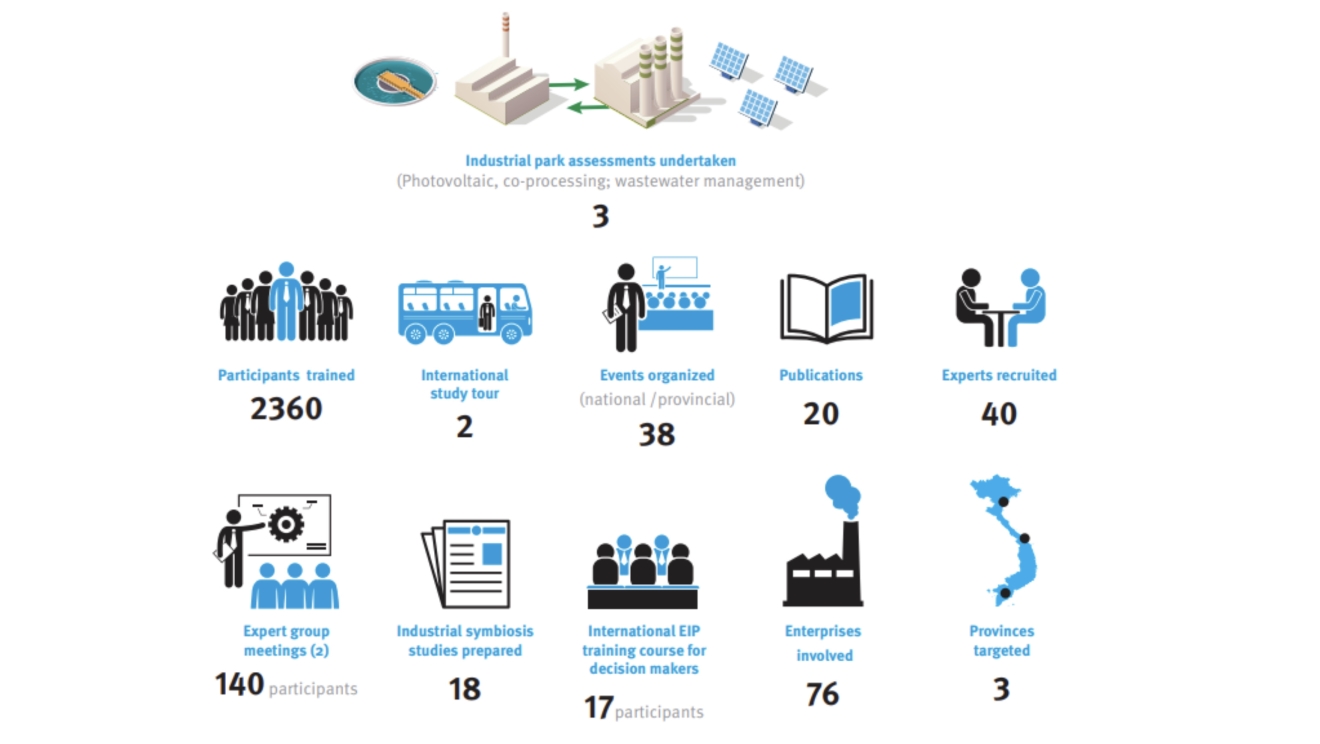

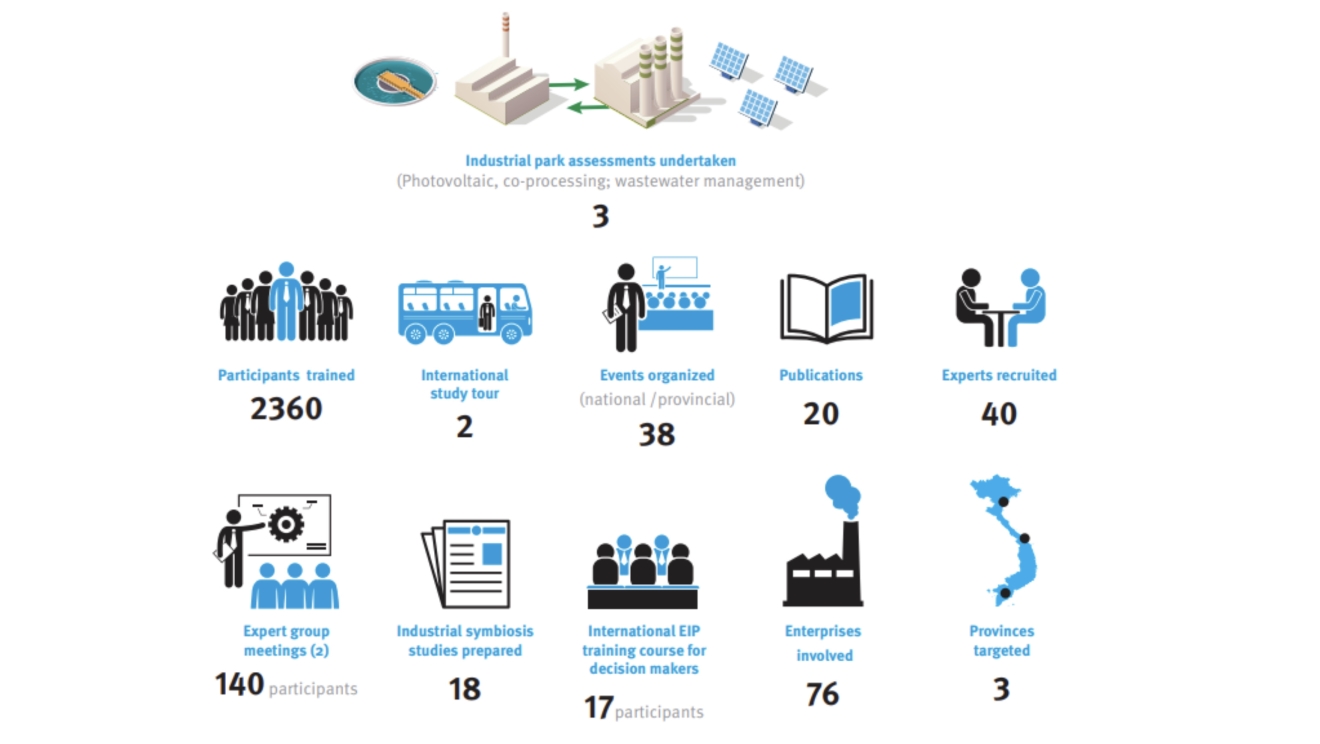

Since the beginning of this century Viet Nam has experienced years of rapid economic growth, driven mainly by the processing and manufacturing sectors. By 2013, the government had established 173 industrial zones, with an average of 90 companies in each zone. Basic environmental legislation had been passed but regulation and enforcement capacity was weak. As a result, approximately 70% of effluents from industrial zones was directly discharged without prior treatment causing severe pollution of surface and groundwater, as well to the marine ecosystems. Untreated solid waste with a high proportion of hazardous material was also on the rise in industrial zones. The fast-paced economic development depended on a high consumption of natural gas, electricity and especially coal, resulting in a rapid increase of greenhouse gas (GHG) emissions.

While the creation of industrial zones has been recognized as an effective way of increasing synergies among industrial activities, thus increasing resource use efficiency, and offering shared infrastructure and services, it is now largely understood that industrial zones can potentially also have negative impacts.

In this context, the United Nations Industrial Development Organization (UNIDO) and Viet Nam’s Ministry of Planning and Investment, with support from the Global Environment Facility (GEF) and the Government of Switzerland, teamed up to transform conventional industrial zones in Viet Nam. Together they implemented an eco-industrial park initiative for sustainable industrial zones in Viet Nam, which was successfully completed in mid-2019. The project focused on increasing the transfer, deployment and diffusion of clean technologies and practices for the minimization of hazardous waste, GHG emissions, and water pollutants, and the sound management of chemicals in industrial zones of Viet Nam.

Broadly, an eco-industrial park (EIP) can be defined as a dedicated area for industrial use at a suitable site that ensures sustainability through the integration of social, economic, and environmental quality aspects into its siting, planning, management and operations. Over time, the EIP concept has evolved to address additional, inter-related aspects, including resource efficient and cleaner production, industrial symbiosis, climate change, pollution, social standards, shared infrastructure, improved spatial zoning and management.

UNIDO’s five-year project aimed to increase the transfer, deployment and diffusion of clean and low-carbon technologies, the minimization of greenhouse gas (GHG) emissions, persistent organic pollutants (POPs) and water pollutants, as well as improving water-efficiency and sound management of chemicals. The project promoted and supported the gradual transformation of industrial zones into eco-industrial parks. In parallel, it also raised enterprise awareness on making optimum use of natural resources, minimizing environmental pollution, while providing positive socio-economic benefits to workers and communities nearby.

An important part of the UNIDO project related to government policies in support of eco-industrial parks. The project played a key role in the preparation of Decree 82, published in May 2018, which defines, inter alia, the conditions and requirements for recognition as eco-industrial parks in Viet Nam (Articles 40-44), as well as prescribing the planning, establishment and operation of policies on and state management of industrial parks and economic zones.

While welcoming the Decree, Tran Duy Dong, General Director of Viet Nam’s Ministry of Planning and Investment, said, “The implementation of the Decree offers a lot of opportunities, but also faces constraints in Vietnamese legislation, as concrete opportunities to develop symbiosis are still limited by regulation.”

UNIDO experts worked with 73 companies located in four industrial zones, namely Khanh Phu IZ and Gian Khau IZ (Ninh Binh), Hoa Khanh IZ (Da Nang) and Tra Noc 1 & 2 IZs (Can Tho), to identify opportunities to optimize their production process and to tackle inefficiencies. Training was also provided to improve the companies’ capacity to implement possible industrial symbiosis. By the end of the project in June 2019, out of a total of 18 industrial symbiosis opportunities and corresponding feasibility studies, 12 opportunities had already been implemented, were under implementation and or were planned. If all opportunities are implemented, 70.5 KtCO2/year, 885,333 m3 of freshwater and 84,444 t of waste are expected to be saved every year. The payback time for these opportunities ranges between three months and eight years.

In addition, a total of around one thousand resource efficiency and cleaner production (RECP) options were identified, of which 546 were implemented in 57 companies. These RECP options implemented led to reductions in the use of electricity (19,274 MWh per year), fossil fuels (142 TJ per year), greenhouse gas emissions (30,570 tCO2eq per year), water (488,653 m3 per year), and of materials/chemicals (3,121 t per year). The options resulted in financial savings of €2.9 million per year, with an average payback time of seven to eight months.

Nguyen Thi Kieu Duyen, Deputy Head of the Can Tho Industrial Zone Authority, said, “Thirty enterprises in Can Tho have been guided to apply cleaner production, safer and sustainable manufacturing in their production processes, resulting in VND 46.56 billion worth of savings per year.” She added, “More than 70 other enterprises have benefited from capacity-building activities, such as training courses on the management of chemicals, RECP identification, implementation, and loan support”.

The main environmental impact of the project will be a significant reduction in greenhouse gas emissions as a result of the innovations and technologies adopted by the enterprises directly involved in the project and by others, not directly involved but which become aware or are informed of the benefits. It is estimated that a total of more than 2,901 kt CO2eq of direct and indirect reductions will be achieved over the next 15 years. This includes a replication factor of three based on the assumption that existing reductions are likely to increase threefold as other enterprises and EIPs follow suit as they see that the practices and technologies introduced by the project have high economic returns and are well within their reach.

For more information, please contact:

Jerome Stucki, Industrial Development Officer, UNIDO

Alessandro Flammini, Project Coordinator, UNIDO

and see:

An International Framework For Eco-Industrial Parks