South Africa's capacity to deploy Fourth Industrial Revolution technologies post-COVID-19

20 November 2021

By Oluseye Jegede, South African Research Chair in Entrepreneurship Education, College of Business and Economics, University of Johannesburg, South Africa

- This opinion piece is part of a series of articles commissioned by UNIDO's Department of Policy Research and Statistics. The views expressed in this article are those of the author based on her experience and on prior research and do not necessarily reflect the views of UNIDO (read more).

COVID-19 has ushered in the Fourth Industrial Revolution in South Africa

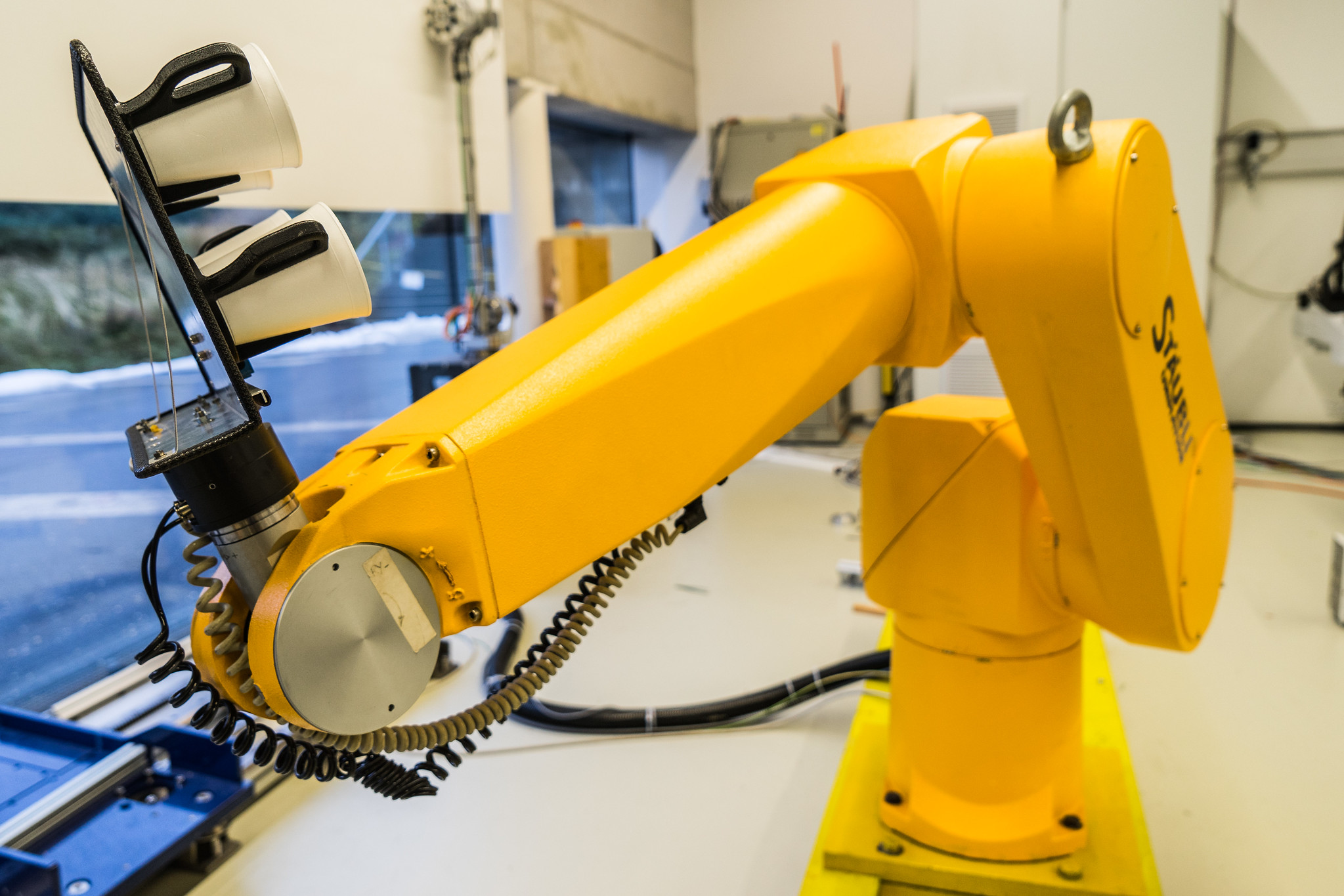

South Africa, which is beset by the triple challenge of income inequality, unemployment and poverty, amidst a prematurely deindustrializing economy, is now facing the realities of a paradigm shift in the way business is done and how we live and work as a result of the disruptions caused by the COVID-19 pandemic. Prior to the outbreak of the pandemic, concerns about the disruptive force of the Fourth Industrial Revolution (4IR) and fears of robots displacing workers were widespread in Africa. Calls in South Africa intensified for government to create more employment and protect jobs in labour-intensive industries from automation. These demands continued until COVID-19 broke out first in China and then rapidly spread around the world. In response to the pandemic, the South African government introduced pivotal measures, including a national lockdown, to contain the spread of the virus. Since the way we work, live and socialize has changed significantly, South Africa has been left with little choice but to embrace the much-dreaded 4IR technologies.

In the meantime, even those at high risk of losing their jobs to automation have come to appreciate the benefits 4IR technologies can offer. South Africans welcomed the possibility of ordering food and medicine online and have them delivered directly to their doorstep. Moreover, artificial intelligence (AI) and mobile technology integrate data collection tools that can be used for contact tracing, symptom monitoring, detection of outbreaks and risk assessment. Employers relied heavily on video conferencing tools such as Zoom, Google Meet and Microsoft Teams. Instead of face-to-face learning, universities and schools moved online using various technological platforms including Ikamva, Blackboard, etc. Researchers continue to use Webex to organize conferences. There are strong indications that many platforms for e-commerce, video conferencing, remote working and telemedicine will continue to flourish long after the pandemic comes to an end.

The 4IR technologies that saw the biggest surge in South Africa during the COVID-19 pandemic include AI in medical diagnosis, the Internet of Things (IoT) for consumer goods, and mobile applications for financial transactions, transportation and utility vending. Other important technologies include digital learning platforms used by universities and schools, augmented and virtual reality in teaching and learning, as well as in entertainment, drones for delivering medicine to rural areas, and 3D printing for medical use.

The history of industrial revolutions and their impacts in South Africa

History has recorded four paradigm shifts in the way industry is structured and in the way we work. The first such shift, the First Industrial Revolution, was premised on scientific discoveries which produced the steam engine and introduced the mechanization of production. The use of steam power in South Africa increased efficiency in mining, agriculture and manufacturing, and accelerated the transportation of goods from manufacturing plants and farms, as well as of diamonds from the mines to the market. The First Industrial Revolution increased productivity in manufacturing and accelerated transportation.

The Second Industrial Revolution integrated scientific knowledge into technological developments, leading to electrification used to power equipment, machinery and tools, thereby introducing the assembly line and mass production. Electricity in South Africa was first used to light up mine tunnels to increase workers’ productivity. Mine workers could now work extended hours and run more shifts. The use of electricity eventually spilled over into industry, cities and private homes.

The Third Industrial Revolution was largely based on the discovery of the semiconductor chip, making the digital revolution possible. IBM set up its first major office in South Africa in 1952, signifying the advent of the Third Industrial Revolution in the country. The next industrial revolution, also known as the ‘second wave of the internet’ was already on the country’s heels by the time South Africa had finally caught up and could contribute to the development of Third Industrial Revolution technologies.

The Fourth Industrial Revolution is characterized by intelligent machines, enabling human-machine interaction to achieve ever higher productivity. It is fuelled by an increasing number of digital connections between people and machines and has led to new technologies including artificial intelligence, augmented reality, blockchain, drones, the Internet of Things, robotics, virtual reality, 3D printing and simulations. COVID-19, in turn, has accelerated these technology trends in South Africa and beyond, but their use remains limited. It can be argued that South Africa is still stuck in the Second and Third Industrial Revolutions.

Has the COVID-19 pandemic spurred South Africa’s preparedness for the Fourth Industrial Revolution?

According to South Africa’s 1996 and 2019 White Papers on Science and Technology, the country follows a ‘linear model of innovation’ with a focus on increasing investment in research and development (R&D) and on creating strong science and technology institutions with an emphasis on linkages and interactions within the national innovation system. The COVID-19 pandemic has opened a unique opportunity for closer collaboration between the key actors of South Africa’s innovation system.

Following the outbreak of the pandemic, the government, industry and universities rushed to cooperate to mitigate the impacts of the crisis. South African universities collaborated with the national and local governments and industry to produce personal protective equipment (PPE) and ventilators. For instance, among others, the Cape Peninsula University of Technology cooperated with the provincial government of the Western Cape and the Department of Trade and Industry to develop and manufacture PPE for frontline workers and the general public. The Central University of Technology’s Centre for Rapid Prototyping and Manufacturing (CRPM), the Product Development Technology Station (PDTS), the Centre on Quality of Health and Living (CQHL) and CUT Innovation Services (CUTis) have been working together with the Free State Provincial Departments of Health and Education and the private sector to develop hospital equipment and protective gear for public use. An engineering team of the University of Johannesburg designed and developed portable 3D-printed mechanical ventilators with a customizable base plate to simultaneously treat multiple patients. Other tangible outcomes include the production of non-invasive ventilators, oxygen connectors and splitters, mouthpieces/masks, ventilation helmets, shields and hand sanitizer. Some of the intangible outcomes of this collaboration include insights into the socio-economic consequences of COVID-19, technical advice for disease control, health policy advice and healthcare training for local government officials.

South Africa’s national and local governments have played an essential role in creating an enabling environment for knowledge development and innovation. This has been achieved by providing tax and loan repayment holidays, cutting costs, increasing social security grants and making funds available to build health infrastructure. However, the role of universities in knowledge generation throughout the pandemic can also not be overemphasized enough. While South African universities were already engaged in applied R&D before the outbreak of the pandemic, with some of the universities’ research outputs being integrated into the country’s manufacturing system, the accumulated research, knowledge and technology was not adequately being incorporated into the country’s broader innovation system. Increased integration of research outputs can only be achieved in cooperation with industry, which ensures that research conducted at universities is demand-driven and problem-based.

The COVID-19 pandemic resulted in changes in South Africa’s private sector as well. 4IR technologies are being implemented to varying degrees depending on the firms’ capabilities. Those that could not deploy these technologies have either shut down or had to close temporarily. Although digitization and automation already began developing during the Third Industrial Revolution, we are now witnessing an increasing integration of such technologies in how we work and live.

Overall, the South African government, industry and universities have weathered the storm unleashed by COVID-19 quite well. The responses to the pandemic’s disruptions are just the beginning of South Africa’s experience with 4IR. Yet the interventions developed by universities in collaboration with the government and industry might not be sustainable when looking at South Africa’s current innovation and industrial policies. The country’s research intensity (gross expenditure on R&D as a percentage of its gross domestic product (GDP)) hovers at around 0.7 per cent. This figure is much lower compared to countries that are already successfully deploying 4IR technologies, e.g. the UAE (1.3%), Brazil (1.26%), China (2.19%), Japan (3.36%), the Republic of Korea (4.81%) and Israel (4.95%) (UNTAD, 2020).

Time-tested strategies for building technological capability for industrialization

Many African countries do not yet have the technological capability to deploy 4IR technologies effectively and efficiently. African policymakers should adopt some time-tested approaches and strategies in their post-COVID-19 recovery plans. Some of the possible approaches and strategies are:

Foreign direct investment (FDI)

Foreign direct investment (FDI) can help promote the exchange of scientific and technological knowledge and accelerates the national diffusion of imported technologies. The highest FDI inflows in South Africa are from Beijing Automotive Industry Holding, BMW, Nissan and Mainstream Renewable Energy, primarily to special economic zones (SEZs). Several European countries (the United Kingdom, Netherlands, Belgium, Germany and Luxembourg), as well as the United States, Japan, China and Australia are active investors in South Africa. Most investments are directed at the financial, mining, manufacturing, transportation and retail sectors. FDI has enhanced labour productivity and promoted the diffusion of skills, knowledge and competencies from SEZs to the rest of the country. Many developments in South Africa’s automotive industry (e.g. competence building) are attributable to FDI inflow.

Several studies (Liu & Daly, 2011; Liu, Daly & Varua, 2012; Liu, Daly, & Varua, 2014) examine China’s successful foreign investment policies to attract FDI, leading to the diffusion of advanced technologies in the country and subsequently to an increase in manufacturing exports, especially high-tech manufactured goods. China used SEZs and national economic and technology development zones (NETDZ) to advance its economic development by attracting FDI. This is one possible avenue South Africa could pursue to accelerate the diffusion of 4IR technologies in the country.

Acquisition of external knowledge

Patents and other intellectual property rights (IPRs) (industrial designs, trade secrets) are eventually transferred from the technological frontier to developing countries. Developing countries thereby gain access to knowledge and technology developed at the global frontier (Saggi, Maskus, & Hoekman, 2004; Hutchison, 2006). The OECD (2018) classifies intellectual property acquisition as an ‘innovation activity’, while the adaptation and modification of such intellectual property is considered ‘innovation’. South Africa is well positioned to leverage intellectual properties and imported technologies from Europe, the United States and Asian countries to spur the spread of 4IR technologies.

Trade of technology-intensive products

Several studies link the trade of new products and production technologies to industrialization. The pioneering study of Dagenais, Mohnen & Therrien (1997) on Canada’s manufacturing sector finds that the output elasticity of foreign R&D trade is more important than that of domestic R&D. The study of Bernstein, & Mohnen (1998) concludes that significant knowledge transfers occurred between the United States and Japan through trade in technology-intensive products between the two countries. A similar study by Eaton and Kortum (1995) involving 19 OECD countries shows that trade in technology-intensive products facilitated technology-intensive spillovers. A low technological gap and high absorptive capacity are crucial if imported technologies are to be absorbed with the aim of advancing industrial development. Sjöholm (1996) asserts that technology proximity and international trade positively influenced the inflow of knowledge to Sweden. South Africa should therefore focus more heavily on the trade of new technologies to ensure that it is not left behind by the 4IR.

Reverse engineering and imitation

Lee & Lim (2001) highlight the importance of imitation and reverse engineering for industrial growth and innovation. Frost (1997) explores the Republic of Korea’s remarkable development from a subsistent agricultural economy to a newly industrialized economy within just 30 years based on imitation and reversed engineering in the automobile, electronics and semiconductor industries and the active promotion of small and medium enterprises (SMEs). Today, the Republic of Korea is a major global player in the semiconductor industry. Semiconductor firms in the Republic of Korea started copying imported technologies until they acquired sufficient knowledge and competence to develop their own brand based on their own technology. Hikino & Amsden (1994) highlight one of the benefits of late industrializing economies: the possibility to adopt and adapt technologies imported from industrialized countries. They explore the cases of Japan, the Republic of Korea, Brazil and Mexico, which succeeded to industrialize by borrowing and improving technologies developed by more experienced firms in more advanced economies. South Africa could also leverage reverse engineering to advance industrialization and the diffusion of new technologies.

R&D and technology consortia

Establishing R&D and technology consortia with countries at the frontier of 4IR technologies is another viable option for South Africa. This approach proved particularly effective in Asia. Mu & Lee (2005) and Lee (2005) investigate the development of R&D consortia in the Republic of Korea and in China. China’s telecommunication industry was able to catch up based on knowledge diffusion from Shanghai Bell to the CIT-led R&D consortium and Huawei.

R&D consortia minimize both the risks and high costs associated with new technology development. The objective of R&D collaboration in South Africa should be the bringing together of firms, research institutes, government agencies and the financial sector within a distinct institutional framework. Studies of Asian countries (Lee, Park & Krishnan, 2014; Lee, Gao & Li, 2017; Lee, 2019; Lee, 2021) show that technological capabilities continue being built through technology transfers and spillovers that result from collaborative R&D and collaborative technology developments. South African policymakers should support the establishment of such consortia to drive the country’s industrialization.

Closing remarks

South Africa’s response to the COVID-19 pandemic has for the most part been quite effective, but is not yet in a position to deploy the entire range of currently available 4IR technologies to assuage the pandemic’s large-scale disruptions and improve the efficiency of its manufacturing sector (with the exception of its automobile industry). While South Africa’s research and innovation system is characterized by strong institutions, the relatively low level of interaction among the innovation system’s key actors continues to hamper South Africa’s capacity to fully deploy 4IR technologies. The country’s innovation policies must be aligned with its innovation system, which encourages collaborative production of knowledge, technology and innovation. Closer coordination between South Africa’s internal resources (financial, human, natural, physical and institutional) and its external ones (FDI, trade in technology-intensive products, acquisition of external technologies, reverse engineering and R&D consortia) could help South Africa build more capacity to leapfrog, and to become a global contributor to the Fourth Industrial Revolution.

- Note: It is now abundantly clear that the COVID-19 pandemic has had an impact on nearly all aspects of our lives and has caused us to rethink “business as usual”. As we adapt to the "new normal", appropriately channelled opportunities can help us improve the way we do business and the way we live. The United Nations Industrial Development Organization is preparing its latest flagship report, the Industrial Development Report 2022, which will provide a comprehensive assessment of the pandemic’s impact on global manufacturing and the prospects for the future of industrialization in a post-pandemic world. Scheduled to be launched on 1 December 2021, the report will make a key contribution to countries' national and international strategies for an inclusive, sustainable and resilient industrial recovery to build back better from the COVID-19 pandemic.

References

Bernstein, J. I., & Mohnen, P. (1998). International R&D spillovers between US and Japanese R&D intensive sectors. Journal of international economics, 44(2), 315-338.

Dagenais, M. G., Mohnen, P., & Therrien, P. (1997). Do Canadian firms respond to fiscal incentives to research and development?, Montreal: CIRANO.

Eaton, J., & Kortum, S. S. (1995). Trade-in Ideas: Patenting and Productivity in the OECD. NBER Working Paper, (w5049).

Frost, C. A. (1997). Disclosure policy choices of UK firms receiving modified audit reports. Journal of Accounting and Economics, 23(2), 163-187.

Hikino, T., & Amsden, A. H. (1994). Staying behind, stumbling back, sneaking up, soaring ahead: late industrialization in historical perspective. Convergence of productivity: Cross-national studies and historical evidence, 285-315.

Hutchison, C. (2006). Does TRIPS facilitate or impede climate change technology transfer into developing countries. U. Ottawa L. & Tech. J., 3, 517.

Lee, K. (2005). Making a Technological Catch‐up: Barriers and opportunities. Asian Journal of Technology Innovation, 13(2), 97-131.

Lee, K. (2019). The art of economic catch-up: Barriers, detours and leapfrogging in innovation systems. Cambridge University Press.

Lee, K. (2021). Economics of technological leapfrogging. The Challenges of Technology and Economic Catch-up in Emerging Economies, 123.

Lee, K., & Lim, C. (2001). Technological regimes, catching-up and leapfrogging: findings from the Korean industries. Research Policy, 30(3), 459-483.

Lee, K., Gao, X., & Li, X. (2017). Industrial catch-up in China: a sectoral systems of innovation perspective. Cambridge Journal of Regions, Economy and Society, 10(1), 59-76.

Lee, K., Park, T. Y., & Krishnan, R. T. (2014). Catching‐up or leapfrogging in the Indian IT service sector: Windows of opportunity, Path‐creating, and moving up the value chain. Development Policy Review, 32(4), 495-518.

Liu, K., & Daly, K. (2011). Foreign direct investment in China manufacturing industry transformation from a low tech to high tech manufacturing. International Journal of Business and Management, 6(7), 15.

Liu, K., Daly, K., & Varua, M. E. (2012). Regional determinants of foreign direct investment in manufacturing industry. International Journal of Economics and Finance, 4(12), 178-192.

Liu, K., Daly, K., & Varua, M. E. (2014). Analysing China's foreign direct investment in manufacturing from a high–low technology perspective. Emerging Markets Review, 21, 82-95.

Mu, Q., & Lee, K. (2005). Knowledge diffusion, market segmentation and technological catch-up: The case of the telecommunication industry in China. Research Policy, 34(6), 759-783.

OECD, E. (2018). Oslo Manual 2018. The Measurement of Scientific, Technological and Innovation Activities, guidelines for collecting, reporting and using data on innovation, 258.

Saggi, K., Maskus, K. E., & Hoekman, B. (2004). Transfer of technology to developing countries: Unilateral and multilateral policy options. The World Bank.

Sjöholm, F. (1996). International transfer of knowledge: the role of international trade and geographic proximity. Weltwirtschaftliches Archiv, 132(1), 97-115.

UNTAD (2020) World Investment Report. [Online] Available at https://unctad.org/system/files/official-document/wir2020_en.pdf accessed 19/08/2021

Universities South Africa report. Engagement and Research in Response to COVID-19 [Online] Available at https://www.usaf.ac.za/covid-19-fosters-a-need-to-re-imagine-the-university-as-a-social-institution/ accessed 19/08/2021